Machinery has a heartbeat. Not literally, but anyone who has watched a production line stop knows the feeling. One missing pallet. One misaligned spindle. One late delivery. Suddenly the day is on fire.

That is why machinery removals to France need more than “a van and a hope.” You need measured planning, stable transport, and a team that treats every load like it has consequences.

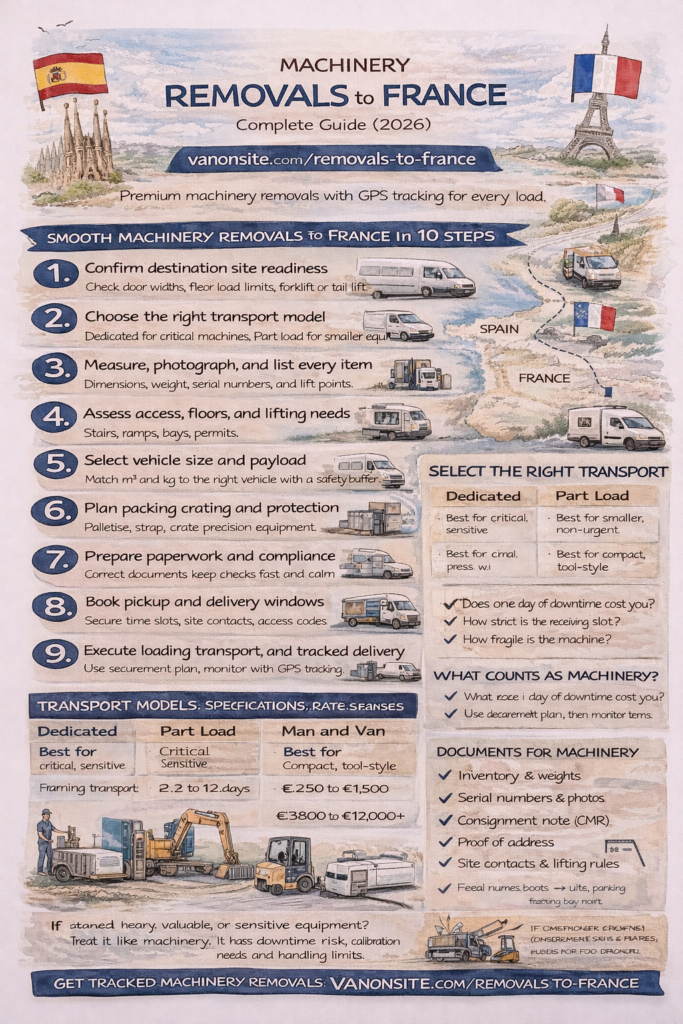

VANonsite delivers premium machinery removals to France with GPS tracking for every load, so you can see progress in real time and keep your schedule under control.

Start here: https://vanonsite.com/removals-to-france/

Quick answer

If you want machinery removals to France to run smoothly, follow this 10 step sequence. It is designed to prevent the most common delays: access issues, missing measurements, and paperwork gaps.

Machinery removals to France in 10 steps

- Confirm destination site readiness

Check door widths, floor load limits, and whether a forklift or tail lift is available. - Choose the right transport model

Dedicated for critical machines. Part load for smaller equipment and spares. Man and van for compact loads. - Measure, photograph, and list every item

Include dimensions, weight, serial numbers, and lift points. - Assess access, floors, and lifting needs

Stairs, ramps, tight corners, loading bays, permits. - Select vehicle size and payload

Match m3 and kg to the right vehicle, with a safety buffer. - Plan packing, crating, and protection

Palletise, strap, and crate precision equipment. - Prepare paperwork and compliance

Correct documents keep checks fast and calm. - Book pickup and delivery windows

Secure time slots, site contacts, and access codes. - Execute loading, transport, and tracked delivery

Use a securement plan, then monitor with GPS tracking. - Unload, position, and sign off

Inspect packaging, confirm serials, and document delivery condition.

What counts as machinery in removals to France

If it is heavy, valuable, full of moving parts, or sensitive to vibration, treat it like machinery. Even “simple” equipment can turn into a costly problem if it arrives out of alignment, dented, or missing its accessories.

A good rule for machinery removals to France is this: if downtime would hurt, plan it like machinery.

Common categories

These are the most frequent items moved under machinery removals to France.

- Workshop and light industrial machines

- CNC and precision equipment

- Food and hospitality equipment, ovens, mixers, refrigeration

- Medical and lab equipment

- Construction and site equipment

- Warehouse and logistics gear

- Printing and packaging machines

- Pumps, compressors, generators, and air systems

Machinery examples and what they need

| Equipment type | Typical risk | Best protection idea |

|---|---|---|

| CNC, lathes, milling machines | Alignment shift, vibration | Crate or pallet plus shock notes |

| Refrigeration units | Fluid leaks, dents | Upright rules, edge protection |

| Lab devices | Calibration drift | White Glove handling and strict packing |

| Compressors and pumps | Weight concentration | Correct lifting points, stable base |

| Warehouse equipment | Scrapes and impact | Strapping and corner protection |

What makes machinery removals different

With machinery removals to France, the risk is rarely one dramatic moment. It is small mistakes that stack.

- Weight concentration can crack tiles, stress floors, or overload a lift

- Alignment and calibration can shift with vibration if not protected

- Power and fluids can leak if not drained and sealed correctly

- Sharp edges and fragile housings can be crushed by tight strapping without padding

- Delivery slots are strict on industrial sites and city locations, late arrivals can mean rebooking

That is why the planning basics matter so much:

- Measure and weigh each item

- Mark lift points and keep upright rules

- Separate accessories and label them with the same Item ID

- Choose the right transport model, dedicated, part load, or man and van, based on the stakes

If you want machinery removals to France to be safe, treat the move as a controlled operation, not a generic haul.

Why choose VANonsite for machinery removals to France

A machinery move is not just transport. It is continuity. VANonsite plans machinery removals to France to protect both the equipment and the schedule, so your team can keep working and your customers do not feel the gap.

The VANonsite advantage

- GPS tracking for every load so you can plan staff and engineers with confidence

- Premium handling and smart loading plans to reduce vibration, rubbing, and pressure marks

- Fast routing with realistic delivery windows, not fantasy promises

- Flexible options from compact loads to heavy shipments

Services you can add

Choose the support level that matches the stakes.

- Packing Service: https://vanonsite.com/packing-services/

- White Glove Delivery: https://vanonsite.com/white-glove-delivery-service/

- Office removals: https://vanonsite.com/office-removals/

- Storage for staged moves

If the machine is sensitive or high value, pairing machinery removals to France with White Glove handling can reduce damage risk and speed up commissioning.

Choose the right transport model

The best transport option depends on urgency, access, and how replaceable the equipment really is. Most people choose on price first, then regret it at 2 a.m. when the delivery slot slips.

To choose well, make a quick judgement call on three questions:

- What does one day of downtime cost you?

- How strict is the delivery slot on the French site?

- How sensitive is the machine to vibration, knocks, and extra handling?

If downtime is expensive or the slot is rigid, dedicated transport wins more often than people expect.

Dedicated transport

Dedicated machinery removals to France give you the cleanest timeline. The vehicle is assigned to your load and route, which means fewer touch points and less handling.

Best for:

- Critical machines

- Fixed delivery slots

- Long distance moves where delays are expensive

- Precision equipment that should be handled as little as possible

What dedicated typically improves:

- Predictability for engineer bookings

- Lower handling risk because the load is not reshuffled

- Faster transit rhythm since routing is built around your delivery

If your site has a strict booking window, dedicated transport can be the difference between a clean handover and a rescheduled day.

Part load and shared routes

Part load is a smart choice for smaller machinery, spares, and flexible schedules. You pay for the space you use and share routing with compatible loads.

Best for:

- 1 to 15 m3 loads

- Flexible delivery windows, often 3 to 7 days

- Non urgent equipment and replacement parts

When you can be flexible, part load can reduce costs by 10% to 25% on many routes.

How to make part load feel safer:

- Palletise and strap, do not leave loose cartons

- Use clear labels with Item ID and lift points

- Avoid shipping ultra sensitive calibration equipment without crating

Part load is value, but value works best when the load is protected and the schedule has breathing room.

Man and van for small machinery loads

A man and van option is ideal when the load is compact, access is tight, and speed matters more than scale.

Best for:

- 1 to 5 m3 of tools, parts, and compact equipment

- Single small machine moves with manageable weight

- Urban pickups with tight access

Typical examples:

- A boxed set of parts and tooling for a maintenance job

- A small workshop machine that is palletised and labelled

- Hospitality equipment like compact units when weight stays within limits

For machinery removals to France, man and van works best when you keep the load tidy, stable, and clearly documented.

Quick decision table

| Your priority | Best option | Why it fits |

|---|---|---|

| Fixed dates, high stakes | Dedicated | One route, fewer handoffs |

| Best value with flexibility | Part load | Pay for space used |

| Small equipment shipment | Man and van | Lean, fast, practical |

| Precision, premium handling | Dedicated plus White Glove | Less vibration, careful placement |

A simple scoring method

If you want a fast choice, score each factor from 1 to 5.

| Factor | 1 | 3 | 5 |

|---|---|---|---|

| Delivery slot strictness | Flexible | Limited window | Appointment only |

| Machine sensitivity | Robust | Moderate | High precision |

| Downtime cost | Low | Medium | High |

If you score 10 or more, dedicated transport is usually the smart call for machinery removals to France.

Site survey and risk planning

Most delays in machinery removals to France come from one cause: the machine fits in theory, but not in the building. A site survey is not paperwork. It is insurance against wasted labour and missed delivery slots.

Think of it as three layers:

- Can the machine move out of the origin building?

- Can it travel safely?

- Can it move into the destination building without improvisation?

Essential checks before pickup

Start with a simple walk through. Then write the numbers down.

- Door widths, corridor width, and turning points

- Lift dimensions and lift weight limits

- Stairs, ramps, gradients, and threshold lips

- Floor loading limits and fragile surfaces

- Parking, permits, height restrictions, and loading bay rules

A small detail can change everything. If parking is 30 metres away instead of 5 metres, handling time can increase by 20% to 40%.

Access details that people forget

These are the quiet traps that derail machinery removals to France.

- Ceiling height at doorways and under sprinklers

- Handrail clearance on stairs and ramps

- Lift door timing and building rules for bookings

- Surface type in corridors, stone, tiles, resin, soft vinyl

- Noise restrictions or limited working hours on site

- Security processes like gate passes and ID checks

A fast risk rating

Use this to prioritise what needs extra planning.

| Risk level | What it looks like | What you do |

|---|---|---|

| Low | Wide access, ground floor, easy parking | Standard palletising and straps |

| Medium | Some stairs, tight turns, limited parking | Add skates, extra protection, longer slot |

| High | Heavy machine, lift limits, strict booking | Dedicated transport, lift plan, White Glove |

If your move feels high risk, treat the delivery slot like a surgical appointment. You want the right tools on site before the vehicle arrives.

Pre move measurements that prevent delays

Create a simple spec sheet for each machine. Do not rely on memory. People forget the extra 8 cm of a handle, and that 8 cm becomes a wall.

- Footprint and height

- Weight per item

- Centre of gravity notes

- Lift points and fork pockets

- Disassembly needs

Simple measurement template

| Field | Example |

|---|---|

| Machine name | CNC mill, Model X |

| Dimensions | 180 x 160 x 210 cm |

| Weight | 1200 kg |

| Lift points | Fork pockets, rear |

| Notes | Keep upright, shock sensitive |

The five photos that make quotes accurate

For machinery removals to France, photos are often the difference between a smooth day and a day of delays.

Take:

- The machine from all 4 sides

- The machine label plate and serial number area

- The route out of the building, including corners

- The pickup parking area and the loading point

- The delivery access route and unloading zone

If there is a tight staircase or narrow lift, photograph it with a tape measure visible.

Disassembly and accessory control

Machinery moves fail when accessories go missing.

- Bag screws and bolts, label them, and tape them to the correct part

- Remove loose panels, shelves, and trays

- Pack tooling separately and label it with the same Item ID

- Keep manuals and commissioning notes in your admin folder

If you are moving multiple machines, create a simple accessory log. It can reduce setup delays by 10% to 30%.

Vehicle sizes for machinery removals to France

The right vehicle is the smallest one that fits comfortably and stays within payload. Tight packing is where damage starts. A good vehicle match protects the load and keeps handling efficient.

For machinery removals to France, use three numbers:

- Volume in m3

- Weight in kg

- The longest side length, because some machines are awkward even when volume looks low

VANonsite fleet overview

| Vehicle package | Volume | Max payload | Typical fit |

|---|---|---|---|

| Moving One | 1 m3 | 100 kg | Tiny shipments, documents, small parts |

| Moving Basic | 5 m3 | 300 kg | Compact equipment and boxed tools |

| Moving Medium | 10 m3 | 500 kg | Small machine plus pallets or crates |

| Moving Premium | 15 m3 | 1100 kg | Larger equipment, multiple pallets |

| Moving Premium Plus | 30 m3 | 3500 kg | Multi pallet loads and heavier machines |

| Moving Full House XXL | 90 m3 | 20000 kg | Heavy, high volume moves |

What fits by real world use cases

| Machinery type | Typical load style | Recommended option |

|---|---|---|

| Tooling, spares, boxed parts | 1 to 5 m3 | Man and van or Moving Basic |

| Compact workshop machine | 5 to 10 m3 | Moving Medium |

| Precision equipment with crate | 10 to 15 m3 | Moving Premium plus protection |

| Multi pallet workshop move | 15 to 30 m3 | Moving Premium Plus |

| Full site relocation | 30 to 90 m3 | Dedicated plus Full House XXL |

Pallet and crate planning shortcuts

If your machinery is palletised or crated, planning becomes easier.

| Unit type | Typical footprint | Typical height range | Planning note |

|---|---|---|---|

| Euro pallet | 120 x 80 cm | 80 to 180 cm | Common for parts and compact units |

| Industrial pallet | 120 x 100 cm | 80 to 200 cm | Better for heavier bases |

| Custom crate | Varies | Varies | Add space for handling clearance |

A practical buffer: add 10% to 15% extra volume for safe loading and protection. This is especially important in machinery removals to France because pressure marks and vibration damage often start with tight packing.

Weight traps

Volume is visible. Weight hides.

- Steel tooling

- Motors and compressors

- Boxes of fasteners

- Fluids and lubricants

- Dense machine bases

Keep most boxes under 20 kg. For heavy parts, use smaller boxes and clear labels.

Weight distribution basics

A load can be under payload and still be risky if weight is poorly placed.

- Heavy items low and stable

- Keep the centre of mass balanced

- Avoid stacking heavy crates on lighter cartons

- Use padding under straps to prevent crushing

If a single item is unusually heavy, note it early. It can change the entire plan for machinery removals to France.

Packing, crating, and protection

The goal is simple: arrive in France with machines that look the same and perform the same.

Protection methods

- Palletising and strapping to create stable units

- Custom crating for precision machines and sensitive components

- Edge and corner protection for panels, housings, and frames

- Moisture control with desiccants and sealed wrap when needed

- Anti rust measures for long routes or humid environments

Labeling that speeds unloading

Good labeling reduces confusion and prevents mistakes.

Include:

- Item ID

- Weight

- Lift points

- Orientation arrows

- Fragile and shock sensitive markers

What not to pack inside the machine

For machinery removals to France, avoid loading loose or risky items inside equipment.

- Loose accessories

- Unsecured tooling

- Unsealed fluids

- Anything that can rattle and damage internals

Pack accessories in separate labeled boxes with the same Item ID.

Loading, lifting, and safe handling

Loading is where machines get damaged. Not because people are careless, but because physics is unforgiving. A single slip can mean a cracked casing, a bent frame, or a calibration drift that shows up a week later like a bad surprise.

For machinery removals to France, aim for one thing: predictable handling. That comes from the right tools, the right sequence, and clear communication on site.

Typical equipment and methods

The best method depends on weight, access, and whether the machine is palletised or loose.

- Tail lift for controlled height changes

- Pallet truck for palletised loads on smooth surfaces

- Machinery skates for heavy bases and tight manoeuvres

- Forklift coordination on site for pallets and crates

- Crane or hiab support when required for awkward lifts

Quick equipment guide

| Situation | Best tool | Why it works |

|---|---|---|

| Pallet or crate, smooth ground | Pallet truck | Fast and stable |

| Heavy base, tight corridor | Skates | Controlled micro movement |

| Loading dock available | Forklift | Lowest handling time |

| No dock, height changes | Tail lift | Safer transitions |

| Over obstacles or limited access | Crane or hiab | Avoids risky dragging |

Safe handling rules that prevent damage

A small set of rules removes most mistakes from machinery removals to France.

- Plan the route before you lift

Walk the path. Measure the tightest point. Remove obstacles. - Know your lift points

Use fork pockets and marked lift points only. Never guess. - Keep heavy items low

Lower centre of mass equals less sway and fewer tip risks. - Protect before you strap

Use padding under straps. Tight straps without padding can crush panels and housings. - Stabilise, then move

If the load shifts under a push, it is not secure enough.

Securement plan checklist

Before the first strap is tightened, confirm:

- Weight per item and total load

- Orientation rules, upright, do not stack, keep level

- Shock sensitive notes for precision equipment

- Strap points that will not crush casings

- Load balance left to right

A simple truth: if a machine is allowed to move even 2 cm in transit, it can arrive as a different machine.

Vibration and shock control for precision equipment

If your equipment is precision grade, treat vibration control as a priority. It is not dramatic, but it is decisive.

Use these tactics:

- Palletise or crate sensitive machines whenever possible

- Add internal bracing inside crates if parts can swing

- Mark shock sensitive items clearly on all sides

- Avoid tight packing that transfers pressure between units

On site coordination that saves time

A good move is often a good conversation.

- Assign one decision maker at pickup and delivery

- Share gate rules and security steps in advance

- Confirm forklift availability and operator timing

- Reserve a clear unloading zone

These steps can cut handling time by 15% to 30% on busy sites.

Documents and compliance for machinery removals to France

Paperwork should be boring. Clear, complete, and instantly readable. That is how machinery removals to France stay fast.

Your goal is simple: anyone checking the shipment should understand what it is, where it is going, and who is responsible, within 60 seconds.

If the move is inside the EU

For Spain to France and other EU to EU routes, you typically need a clear inventory and commercial style documents.

- EU guidance for citizens and businesses: https://europa.eu/youreurope/

Practical tip: even inside the EU, an itemised inventory with serial numbers reduces delays and disputes.

If the move crosses the UK border

If your machinery removals route touches the UK, plan customs properly. Missing customs data can freeze timelines.

- UK guidance on EORI: https://www.gov.uk/eori

- French customs portal: https://www.douane.gouv.fr/particuliers

Recommended paperwork pack

Keep this pack with the site manager and the driver contact.

- Itemised inventory with values

- Serial numbers and photos

- CMR consignment note

- Proof of address and site contact details

- Manufacturer handling instructions, if available

What a strong inventory includes

| Field | Why it matters |

|---|---|

| Item name and model | Clear identification |

| Serial number | Prevents disputes |

| Dimensions and weight | Supports safe handling |

| Value | Helps with insurance and declarations |

| Orientation and lift points | Reduces damage risk |

Restricted and controlled items

Do not move uncontrolled:

- Fuels and aerosols

- Chemicals and hazardous residues

- Contaminated equipment

If a machine contains oils or fluids, confirm draining and sealing plans before pickup. If the equipment is classified as waste or contaminated, treat it as a special case and do not assume it can travel under normal removals.

Timelines and scheduling

Time is money, and downtime is louder than cost. The best timelines are built backwards from the moment the machine must be operational.

Typical planning windows

| Transport model | Typical planning range | Best for |

|---|---|---|

| Dedicated | 2 to 6 days | Critical machines, fixed slots |

| Part load | 4 to 12 days | Flexible windows, smaller loads |

| Man and van | 2 to 8 days | Compact equipment shipments |

A simple scheduling formula

For machinery removals to France, a practical buffer is:

- Transit plan plus 1 to 2 days for access changes

- Add 1 day if the site has appointment only unloading

- Add 1 to 3 days if commissioning engineers must be booked

How to avoid downtime

- Book engineers after the delivery window is confirmed

- Use staged delivery with storage if the site is not ready

- Schedule deliveries for off peak hours when city restrictions apply

- Keep accessories and manuals together so setup starts immediately

Storage can be a lifesaver when keys, access, or site readiness changes.

Machinery removals to France cost

You do not need mystery. You need a range that helps you plan, book engineers, and protect cashflow.

For machinery removals to France, pricing is built from time, handling risk, and how awkward the load is, not just distance. Two shipments can look similar on paper and land 30% apart in cost because one has a tight lift, appointment only unloading, and a machine that must stay perfectly level.

What drives cost most

- Weight and dimensions, especially long or top heavy items

- Access complexity and lifting requirements

- Packing and crating level, plus palletising needs

- Route distance, tolls, and time restrictions

- Timing, peak demand periods can add 15% to 35%

Access complexity alone can change handling time by 20% to 40%.

Cost drivers, made practical

| Cost driver | Typical impact | What to share for an accurate quote |

|---|---|---|

| Weight concentration | Higher handling and equipment needs | Weight per item, not just total |

| Awkward dimensions | Slower loading, more space planning | Longest side length and height |

| Access difficulty | More labour time | Photos of doors, corridors, lifts, stairs |

| Appointment only delivery | Scheduling pressure | Delivery slot rules and contact details |

| Crating level | Higher protection cost, lower risk | Sensitivity notes and manufacturer guidance |

Practical cost ranges

These ranges are planning anchors for machinery removals to France. Exact quotes depend on measurements, access, and dates.

| Load type | Typical example | Typical range |

|---|---|---|

| Light machinery | Tools, parts, small equipment | €450 to €1,500 |

| Medium machinery | Palletised machine, crate, 5 to 15 m3 | €1,200 to €4,500 |

| Heavy machinery | Multi pallet loads, heavy machines | €3,800 to €12,000+ |

Example scenarios you can relate to

These are realistic planning anchors for machinery removals to France, not promises.

| Scenario | What is moving | Typical planning range |

|---|---|---|

| Small workshop shipment | 1 to 3 m3 parts, tooling, boxed accessories | €450 to €1,150 |

| Single palletised machine | 1 pallet or compact crate, manageable access | €900 to €2,900 |

| Precision machine with crating | Shock sensitive unit, strict handling notes | €1,800 to €5,600 |

| Multi pallet relocation | 4 to 10 pallets, mixed weights | €3,500 to €9,500 |

A simple cost calculator

To get a fast estimate for machinery removals to France, use this quick checklist and you will be close:

- Total volume in m3

- Heaviest single item in kg

- Access rating at pickup and delivery: easy, medium, difficult

- Protection level: palletised, wrapped, crated

- Delivery window: fixed date or flexible

If any of these are unknown, the quote will include a risk buffer. Remove the unknowns and you remove the buffer.

How to reduce cost without risk

Cost drops when uncertainty drops. The safest savings are the ones that reduce time and confusion.

- Provide accurate photos and measurements

- Share weights per item and centre of gravity notes

- Offer a flexible delivery window for part load

- Ensure the site is ready, with parking and access confirmed

- Separate accessories and label them clearly

Five extra levers that keep quality high

- Palletise loose items, avoid mixed cartons chaos

- Use small boxes for dense parts, keep most under 20 kg

- Confirm forklift availability and operator timing, late forklifts can add 30 to 90 minutes

- Avoid peak day collections where possible, midweek often prices better

- Keep the route and site rules simple, fewer restrictions means fewer delays

If you want the fastest quote for machinery removals to France, send a photo set plus a one page item list. It can reduce back and forth by 50% and lock the plan quicker.

Delivery day checklist

Delivery day should feel controlled. Calm is a sign of competence.

Before the vehicle arrives

- Clear the access route and protect floors

- Confirm lifting equipment, tail lift, forklift, skates

- Reserve parking or the loading bay

- Share a site contact who can make decisions

On arrival

- Guide placement and keep paths clear

- Check packaging integrity before unwrapping

- Photograph condition and serial labels

- Sign off only after visual inspection is complete

After delivery: setup and commissioning

A good delivery is the start, not the finish.

- Position the machine using the correct lift points

- Allow temperature stabilisation if the equipment is sensitive

- Book engineers after delivery timing is confirmed

- Run quick calibration and function checks

A simple rule: do not rush commissioning. A careful first hour can prevent a painful first month.

FAQ

How long do machinery removals to France take?

Most machinery removals to France land in one of these planning windows:

- Dedicated transport: 2 to 6 days

- Part load: 4 to 12 days

- Man and van: 2 to 8 days

What can stretch the timeline?

- Appointment only unloading, add 1 day buffer

- Tight access or lift bookings, add 2 to 4 hours handling

- Crating requirements, add 1 to 2 days for preparation

Can you move one machine only?

Yes. Single machine machinery removals to France are very common, especially for workshops, hospitality equipment, and lab devices. The key is a clean spec sheet: dimensions, weight, lift points, and photos. With that, the plan becomes fast and predictable.

Do you offer part load machinery removals?

Yes. Part load machinery removals to France are ideal for smaller machines, spares, and flexible delivery windows. If you can offer a delivery window instead of a fixed minute, part load often brings the best value without compromising safety.

Is man and van suitable for equipment?

A man and van option works well for compact equipment and parts, typically 1 to 5 m3, as long as weight and access are manageable. It is a strong fit for:

- Tooling and spare parts shipments

- Compact units that are boxed or palletised

- City pickups where a larger vehicle would struggle

If the item is shock sensitive or unusually heavy, dedicated transport or crating is usually the safer choice for machinery removals to France.

What paperwork is needed from the UK?

If the route crosses the UK border, you may need customs planning and an EORI number. For machinery removals to France, the documents that keep things smooth are an itemised inventory, serial numbers, and clear consignee details.

- UK EORI guidance: https://www.gov.uk/eori

- French customs portal: https://www.douane.gouv.fr/particuliers

What paperwork is needed inside the EU?

For EU to EU routes, machinery removals to France are usually simpler. You still want a clear inventory and proof of destination details.

- EU guidance: https://europa.eu/youreurope/

How do you protect precision machinery?

Precision equipment hates surprises. For machinery removals to France, protection typically includes:

- Palletising or crating to prevent micro movement

- Padding under straps to avoid pressure damage

- Shock sensitive labels on all sides

- Extra space between units so pressure is not transferred

White Glove handling adds careful placement and reduced risk when calibration matters.

Do you offer packing and crating support?

Yes. Packing support is available when you want higher protection and faster site handling.

- Packing Service: https://vanonsite.com/packing-services/

- White Glove Delivery: https://vanonsite.com/white-glove-delivery-service/

Do you offer storage and staged delivery?

Yes. Storage supports phased moves and protects you when site readiness changes. It is also a smart option when you want to move equipment in stages to reduce downtime.

What details do you need for an accurate quote?

For accurate machinery removals to France pricing, send:

- Pickup and delivery postcodes

- Dimensions and weight per item

- Photos from all sides

- Serial numbers if relevant

- Access details: doors, lifts, parking, loading bay rules

- Preferred dates and flexibility window

If you include the five photos from the site survey section plus a one page item list, quote accuracy improves fast and back and forth usually drops by 50%.

Summary

If you take one thing from this guide, let it be this: machinery removals to France are won before the van arrives. When you measure properly, plan access, protect the load, and keep paperwork clean, the move becomes calm, predictable, and fast.

Here is the full picture in a nutshell.

The smart way to plan machinery removals to France

- Pick the right transport model: dedicated for strict slots and high stakes, part load for flexible windows and value, man and van for compact equipment and spares.

- Treat access like a risk factor: doors, lifts, floor limits, parking, and site rules can add 20% to 40% handling time if missed.

- Protect the machine, not just the paintwork: palletise, strap with padding, crate precision equipment, and control moisture when needed.

- Keep accessories under control: label everything with Item IDs, separate tooling, and log small parts so commissioning is not delayed.

- Make documents boring: itemised inventory, serials, photos, and clear site contacts reduce delays and disputes.

Five essentials to keep the move under control

- Item list with photos, measurements, and weights

- Access and lifting plan for both sites

- Protection strategy: pallet, strap, crate, moisture control

- Paperwork pack: inventory, serials, CMR, site contacts

- Delivery window that matches your operational reality

VANonsite delivers premium machinery removals to France with GPS tracking for every load, plus packing, White Glove handling, office support, and storage when you need extra care.

Get started here: https://vanonsite.com/removals-to-france/